Introduction of Light Steel Drywall Machine

The light steel drywall has the characteristics of light weight, high strength, good fire resistance, strong versatility and easy installation, and has the effects of shock proof, dust proof, sound insulation, sound absorption, constant temperature, etc., and also has the advantages of short construction period, simple construction, and not easy to deformation

Product Display

Main Parameters

| No. | Item | Description |

| 1 | Suitable Material | 0.7-1.0mm galvanized steel |

| 2 | Working process | decoiling--guiding&roll forming--hydraulic cutting--products collecting |

| 3 | Speed | 6-12m/min |

| 4 | Machine size | 12*1.5*1.2m |

| 5 | Machine weight | 4 ton |

| 6 | Decoiler | 3T passive decoier |

| 7 | Main motor | 5.5 kw |

| 8 | Forming stations | 12 stations |

| 9 | Driving method | by chain |

| 10 | Material of rollers | GCr15 steel with quench HRC55-58° |

| 11 | Material of cutter | Cr12Mov with quench HRC58-62° |

| 12 | Diameter of shafts | 60mm |

| 13 | Machine structure | 18mm wall panel structure |

| 14 | Production period | 40 days |

| 15 | Delivery container | 20GP*1 |

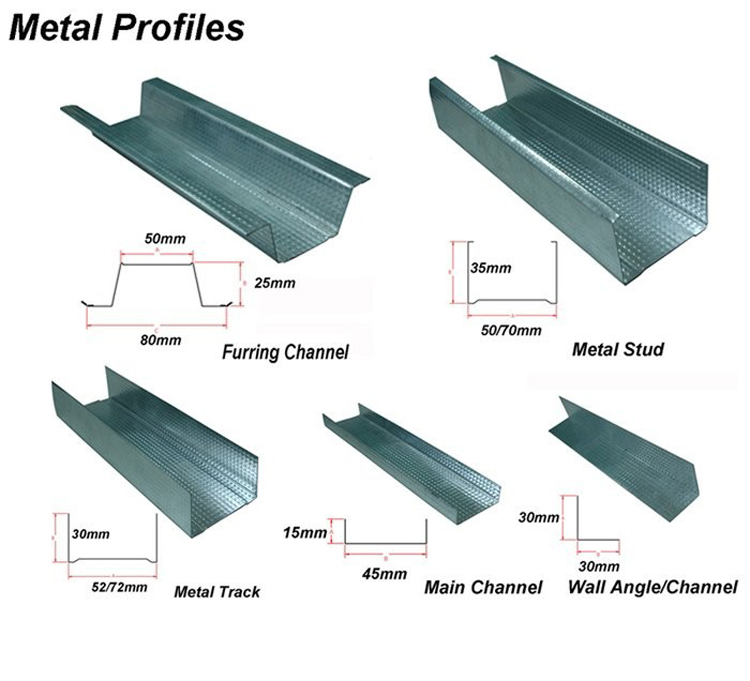

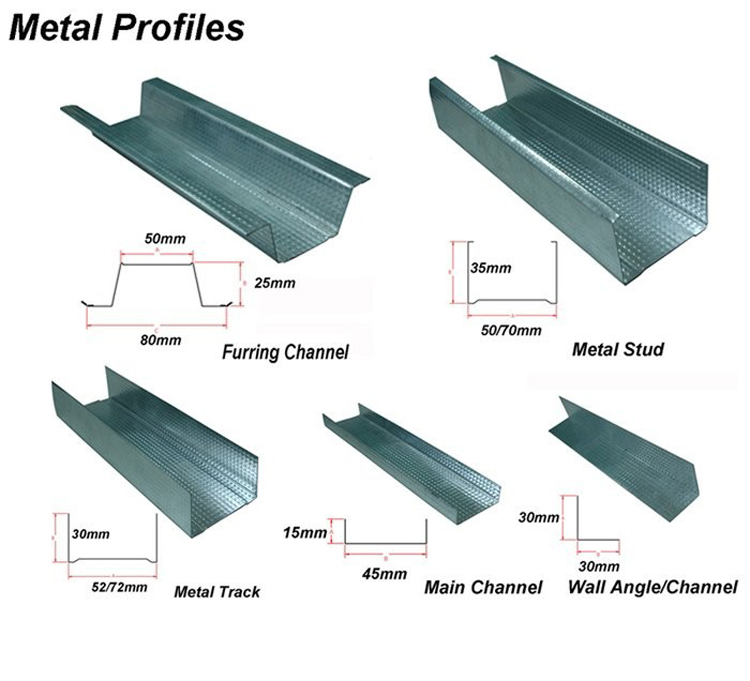

Profile Drawings

Application Scenarios