Introduction

840 900 model Double Layer Roof Sheet Machine adopts double layer design, can produce two models of color steel roof sheet. This design not only saves the cost compared with two machines, but also reduces the footprint of the equipment. 840 and 900 models of roof sheet are widely used in the construction market.

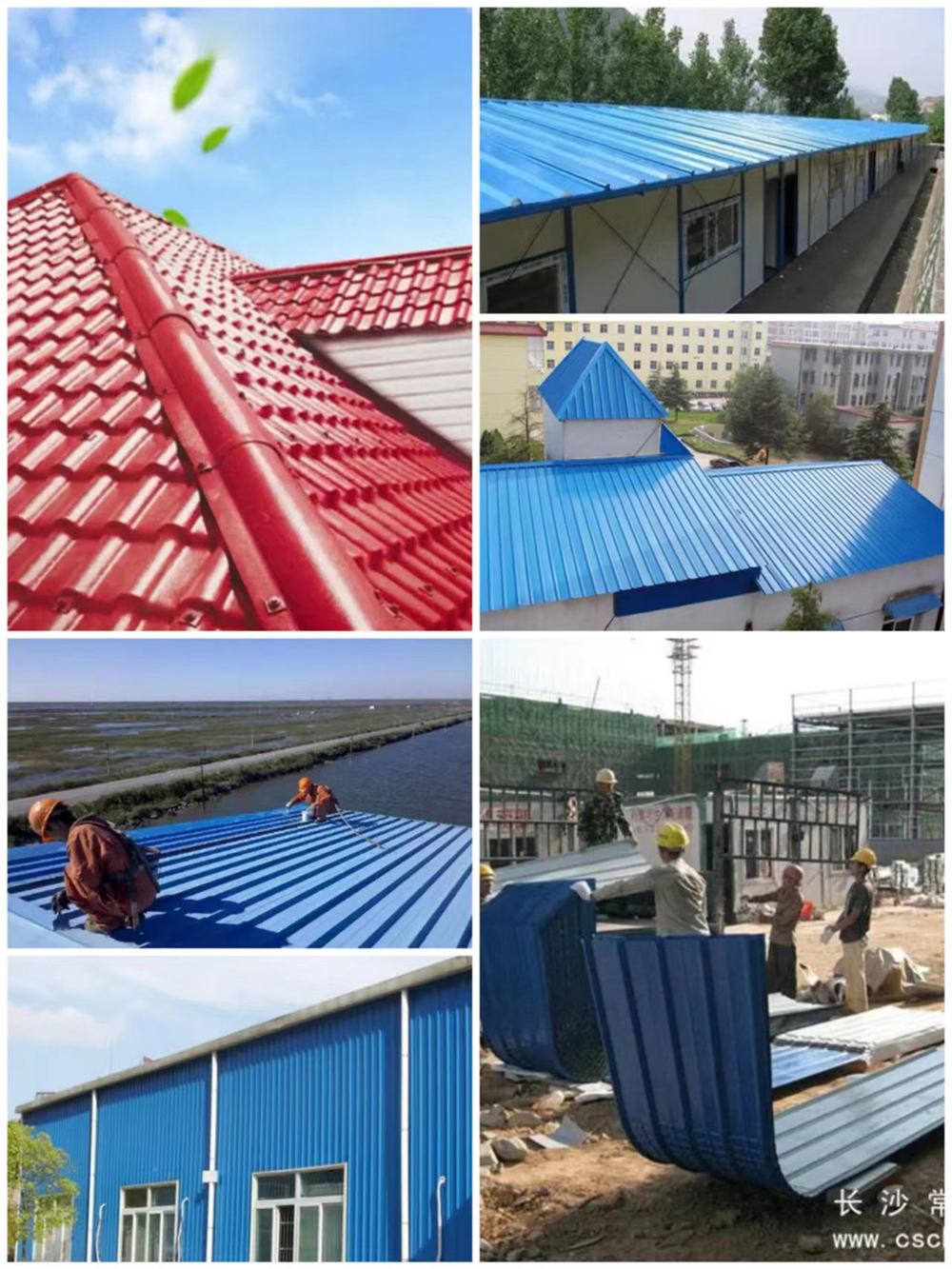

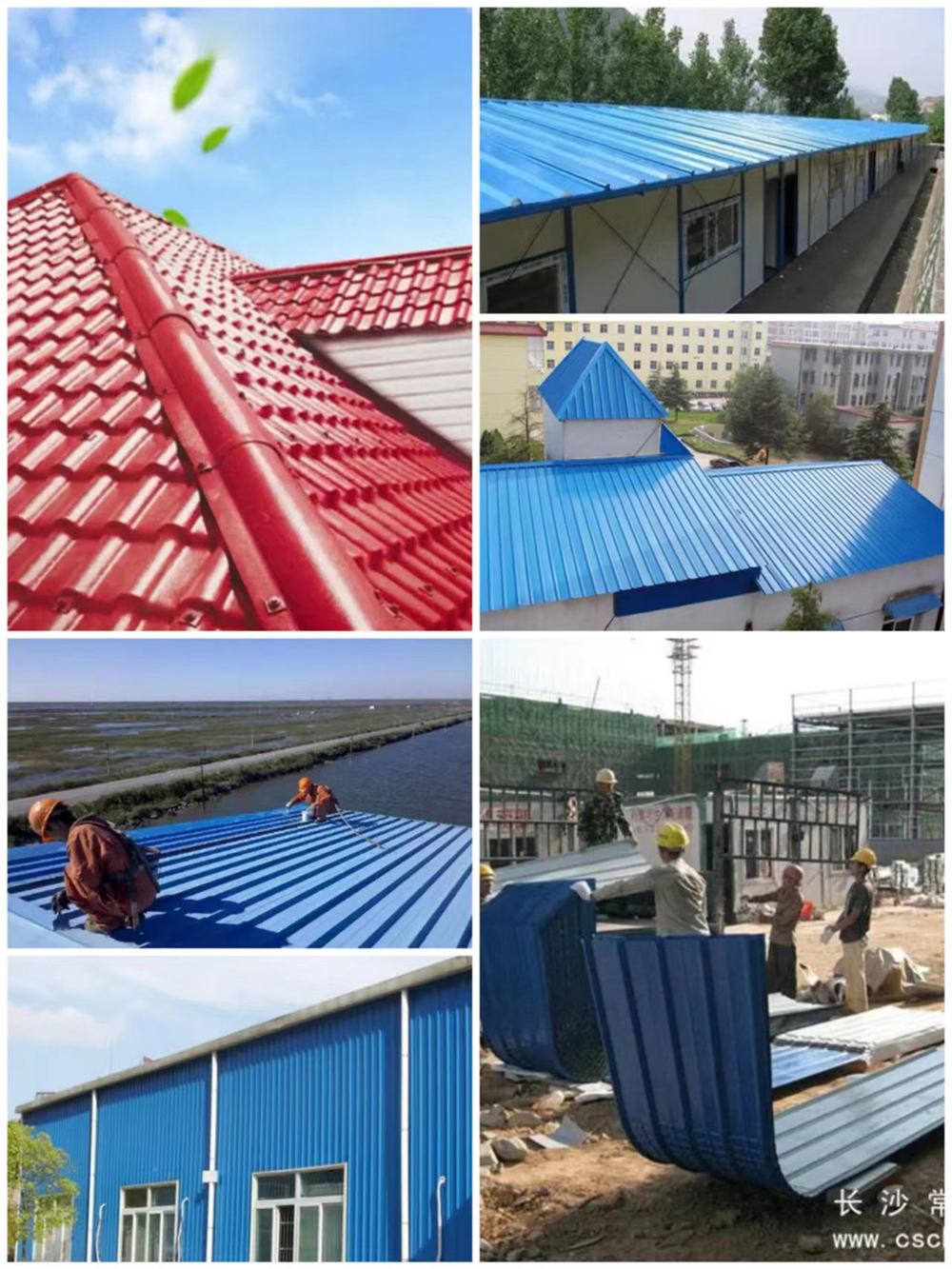

Product Display

| Main parameters of 840 900 Double-layer Roof Tile Machine(can be customized) |

| No. | Item | Description |

| 1 | Suitable Material | 0.3-0.8mm color steel |

| 2 | Working process | decoiling--guiding&roll forming--hydraulic cutting--products collecting |

| 3 | Speed | 6-12m/min |

| 4 | Machine size | 15*1.5*1.2m |

| 5 | Machine weight | 11 ton |

| 6 | Decoiler | 10T passive decoier |

| 7 | Main motor | 7.5 kw |

| 8 | Forming stations | 13 stations and 16 stations |

| 9 | Driving method | by chain |

| 10 | Material of rollers | 45# steel, plated with chrome |

| 11 | Material of cutter | Cr12Mov with quench HRC58-62° |

| 12 | Diameter of shafts | 75mm |

| 13 | Machine structure | 18mm wall panel structure |

| 14 | Production period | 40 days |

| 15 | Delivery container | 40GP*1 |

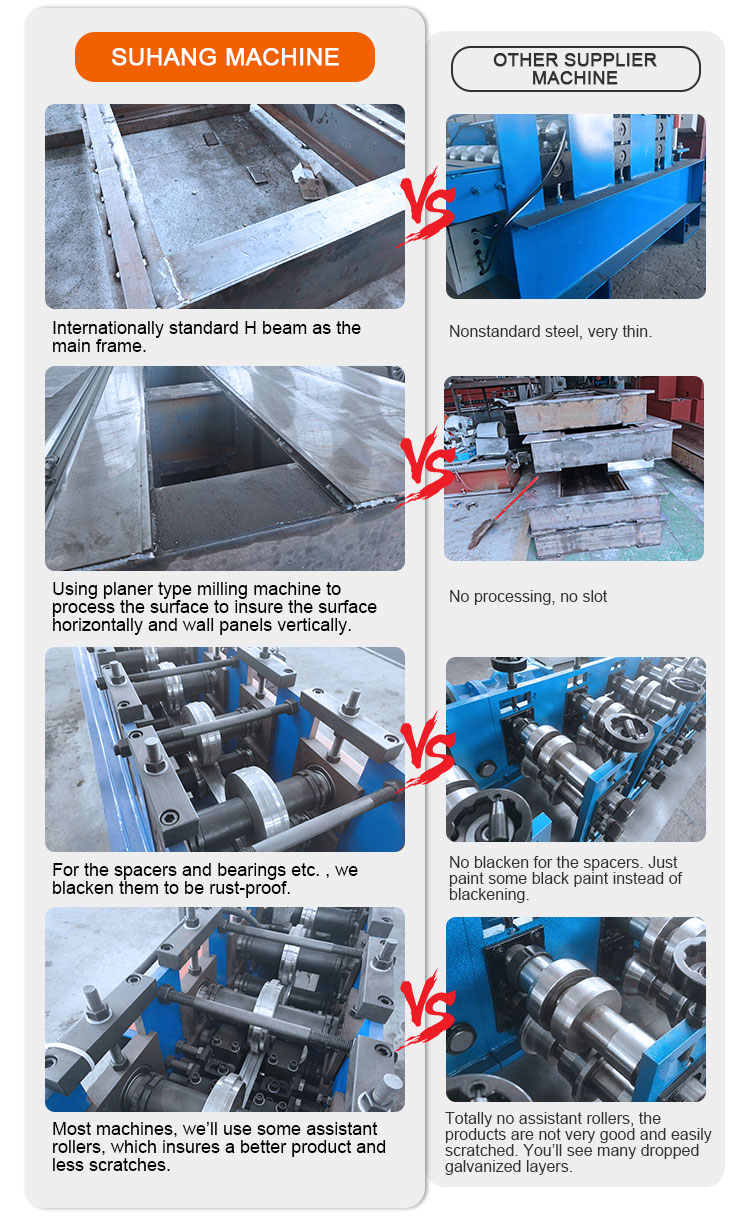

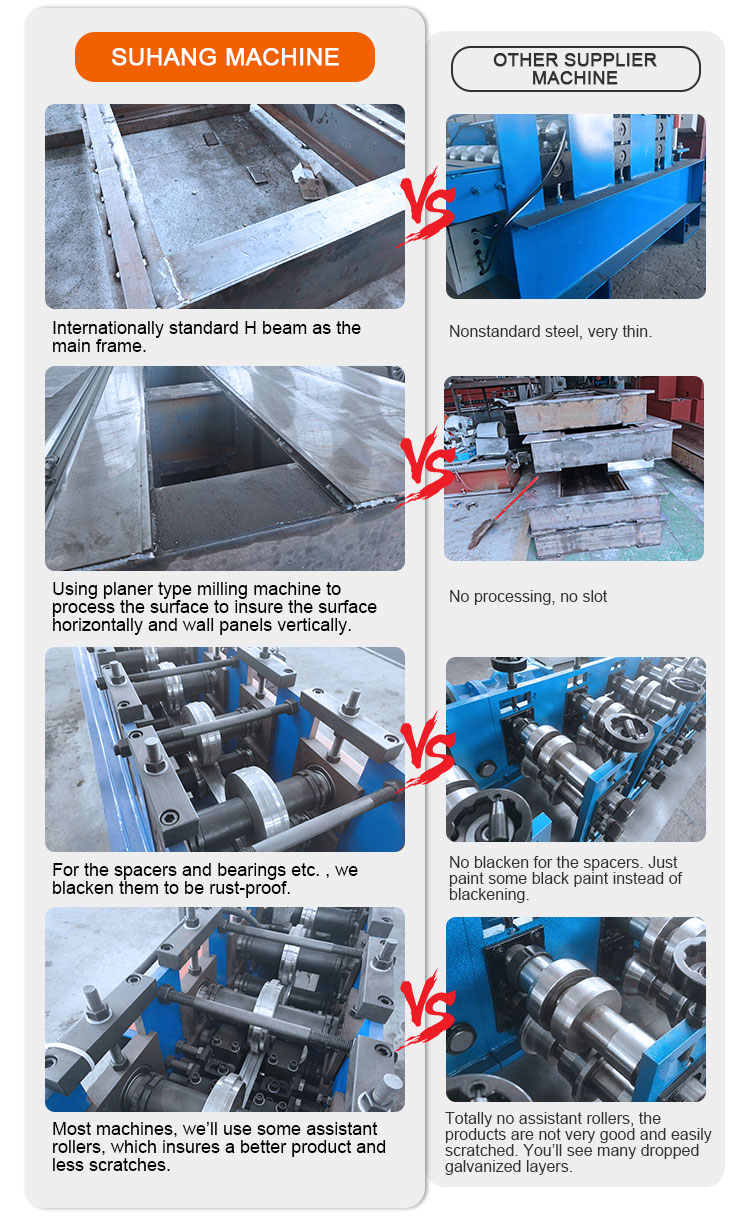

| Advantage of 840 900 Double-layer Roof Tile Machine |

| No. | Item | Description |

| 1 | Solid basic frame | Internationally standard H beam as the basic frame and supporting frame instead of poor thin beam or tubes |

| 2 | Frame processing | With planer type milling machine to process the surface to insure the the wall panels are welded totally vertically to the frame, which guarantee the accuracy of the finished products |

| 3 | Detail oriented | For the spare parts, we'll blacken them to be rust-proof instead of painting some black paints |

| 4 | First-line electrical brands | PLC-- Panasonic VFD-- Yaskawa Encoder--Omron Touch screen-- Mcgs |

| 5 | High accuracy | For most machines,Contour tolerance: ±0.2-0.3mm ;Length tolerance: ±0.5-1.0mm;Holes tolerance:±0.2-0.3mm |

Application

Why Choose Us