Introduction of Electrode Plate Roll Forming Machine

Anode plate is the core component of electrostatic precipitator, anode plate acceptance criteria: flat, high strength, stiffness, not easy to twist. Usually one machine can produce different specifications by changing spacers manually

| Main parameters(can be customized) |

| No. | Item | Description |

| 1 | Suitable Material | 1.0-1.6mm color steel |

| 2 | Working process | decoiling--guiding&hydraulic punching--roll forming--hydraulic cutting--products collecting |

| 3 | Speed | 5-8m/min |

| 4 | Machine size | 20*2.0*1.2m |

| 5 | Machine weight | 15 ton |

| 6 | Specification adjustmnet | adjusted by changing spacers manually |

| 7 | Decoiler | 15T hydraulic decoiler with coil car |

| 8 | Main motor | 30kw |

| 9 | Forming stations | 24 stations |

| 10 | Driving method | by gearbox |

| 11 | Material of rollers | Gcr15 with quench HRC58-62 |

| 12 | Material of cutter | Cr12Mov with quench HRC58-62° |

| 13 | Diameter of shafts | 90mm |

| 14 | Machine structure | casting arch structure |

| 15 | Production period | 70 days |

| 16 | Delivery container | 40GP*1 |

Machine Exhibition

Main Parameter of Electrode Plate Roll Forming Machine

| No. | Item | Description |

| 1 | Suitable Material | 1.0-1.6mm color steel |

| 2 | Working process | decoiling--guiding&hydraulic punching--roll forming--hydraulic cutting--products collecting |

| 3 | Speed | 5-8m/min |

| 4 | Machine size | 20*2.0*1.2m |

| 5 | Machine weight | 15 ton |

| 6 | Specification adjustmnet | adjusted by changing spacers manually |

| 7 | Decoiler | 15T hydraulic decoiler with coil car |

| 8 | Main motor | 30kw |

| 9 | Forming stations | 24 stations |

| 10 | Driving method | by gearbox |

| 11 | Material of rollers | Gcr15 with quench HRC58-62 |

| 12 | Material of cutter | Cr12Mov with quench HRC58-62° |

| 13 | Diameter of shafts | 90mm |

| 14 | Machine structure | casting arch structure |

| 15 | Production period | 70 days |

| 16 | Delivery container | 40GP*1 |

Application of Electrode Plate Roll Forming Machine

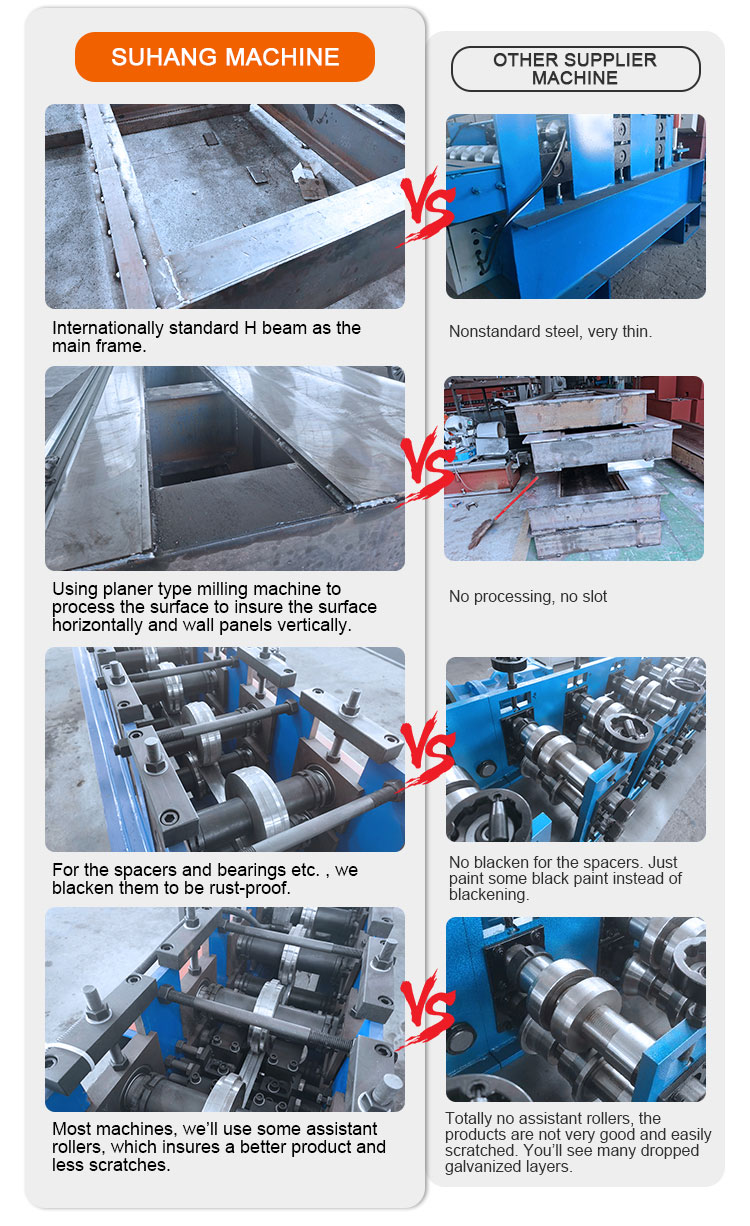

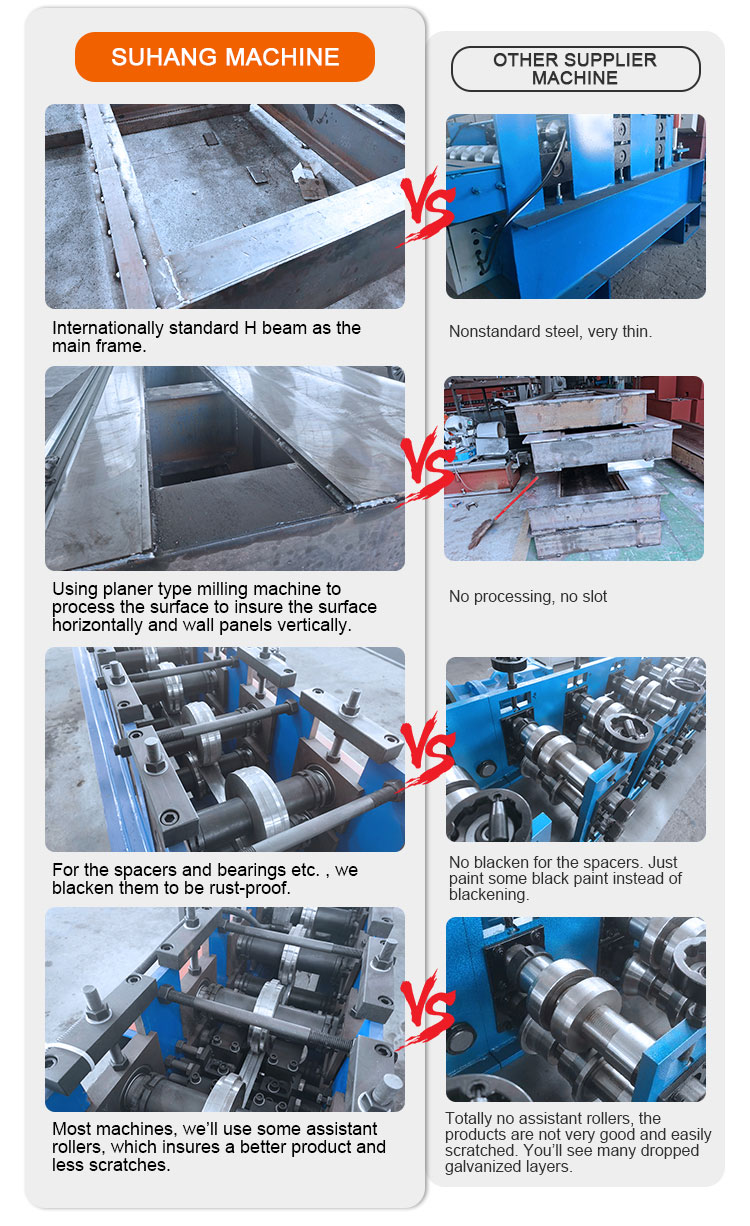

Why Choose Us

Why Choose Us