Introduction of Roof Sheet Machine

Color Steel Roll Forming Machine is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure of the roof, wall and interior and exterior wall decoration, with light weight, high strength, rich color, convenient construction, seismic, fire, rain, long life, maintenance-free and other characteristics, has been widely used

Main Parameters(can be customized)

| No. | Item | Description |

| 1 | Suitable Material | 0.3-0.8mm color steel |

| 2 | Working process | decoiling--guiding&roll forming--hydraulic cutting--products collecting |

| 3 | Speed | 6-12m/min |

| 4 | Machine size | 15*1.5*1.2m |

| 5 | Machine weight | 8 ton |

| 6 | Decoiler | 10T passive decoier |

| 7 | Main motor | 7.5 kw |

| 8 | Forming stations | 22 stations |

| 9 | Driving method | by chain |

| 10 | Material of rollers | 45# steel, plated with chrome |

| 11 | Material of cutter | Cr12Mov with quench HRC58-62° |

| 12 | Diameter of shafts | 75mm |

| 13 | Machine structure | 18mm wall panel structure |

| 14 | Production period | 40 days |

| 15 | Delivery container | 40GP*1 |

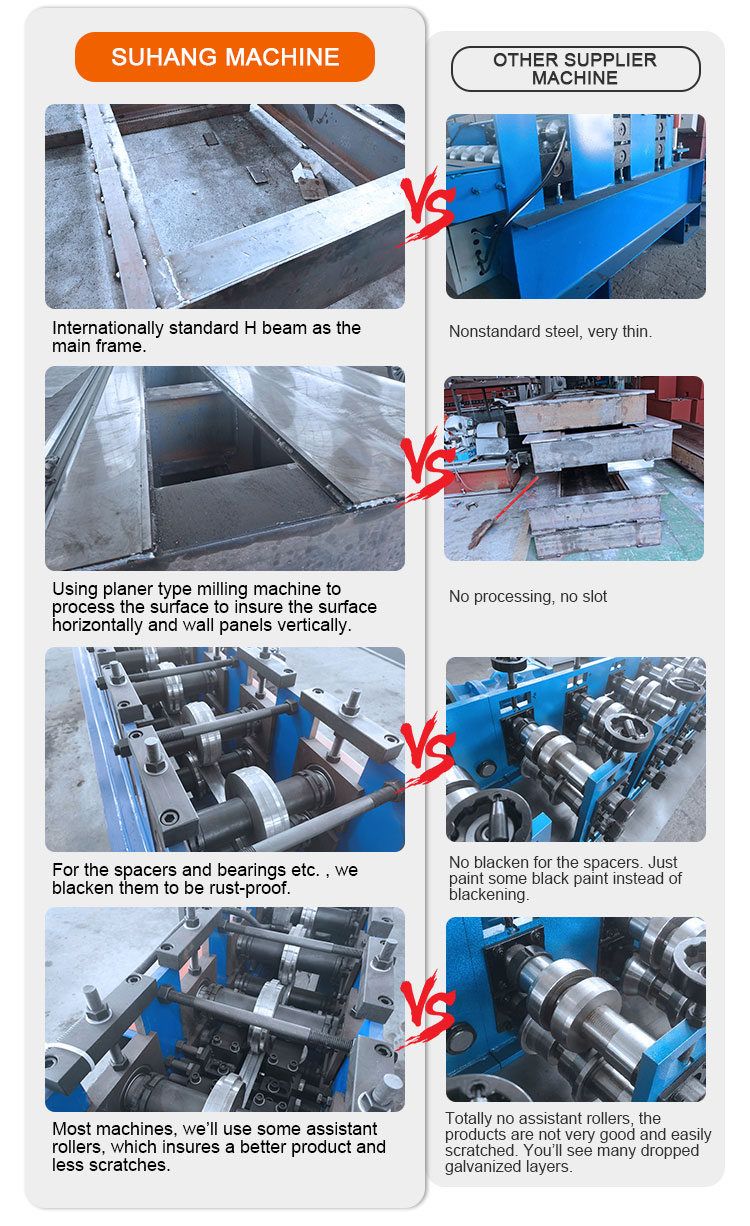

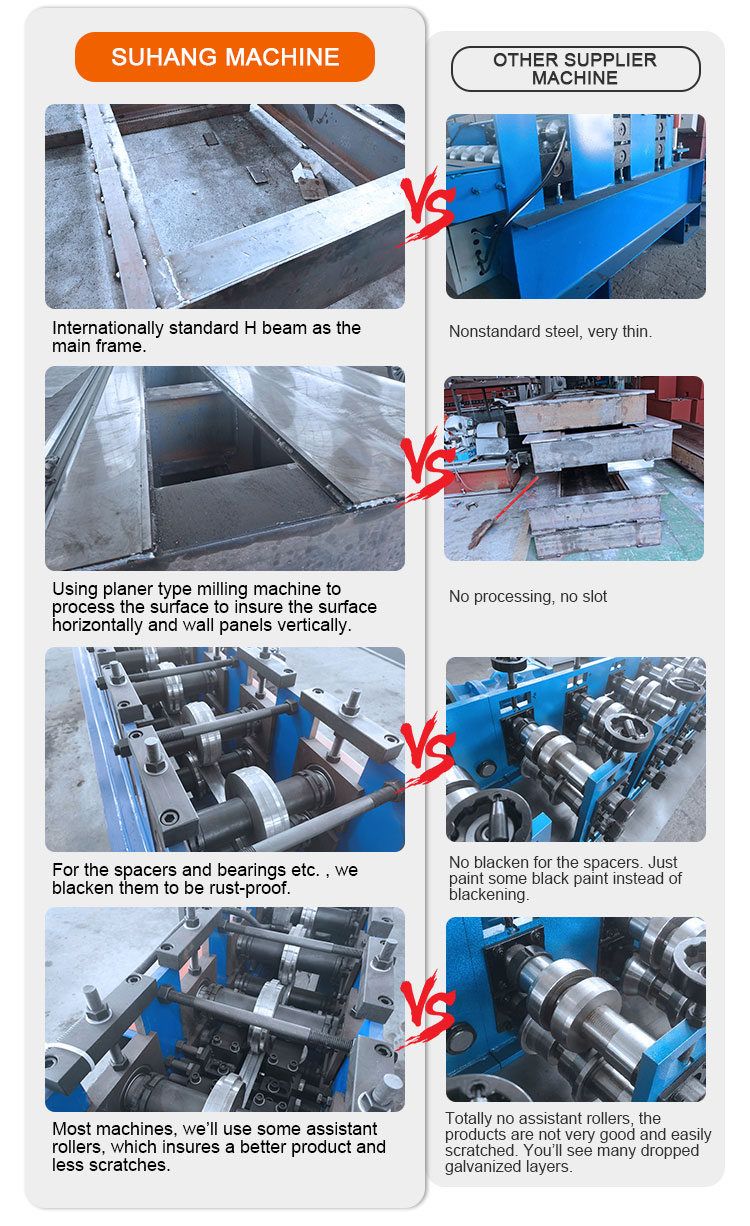

Corrugated Roof Sheet Machine Advantage

| No. | Item | Description |

| 1 | Solid basic frame | Internationally standard H beam as the basic frame and supporting frame instead of poor thin beam or tubes |

| 2 | Frame processing | With planer type milling machine to process the surface to insure the the wall panels are welded totally vertically to the frame, which guarantee the accuracy of the finished products |

| 3 | Detail oriented | For the spare parts, we'll blacken them to be rust-proof instead of painting some black paints |

| 4 | First-line electrical brands | PLC-- Panasonic VFD-- Yaskawa Encoder--Omron Touch screen-- Mcgs |

| 5 | High accuracy | For most machines,Contour tolerance: ±0.2-0.3mm ;Length tolerance: ±0.5-1.0mm;Holes tolerance:±0.2-0.3mm |

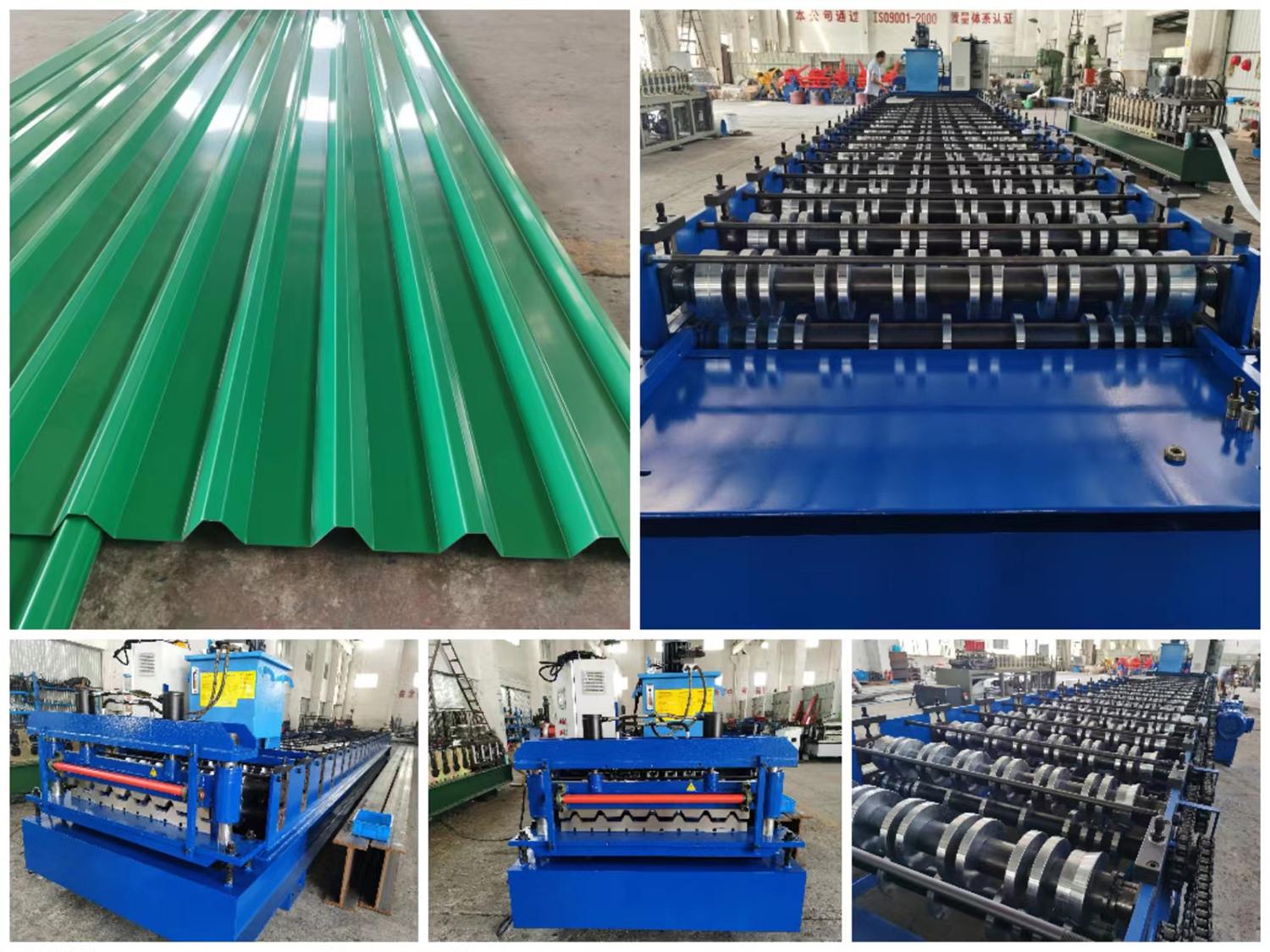

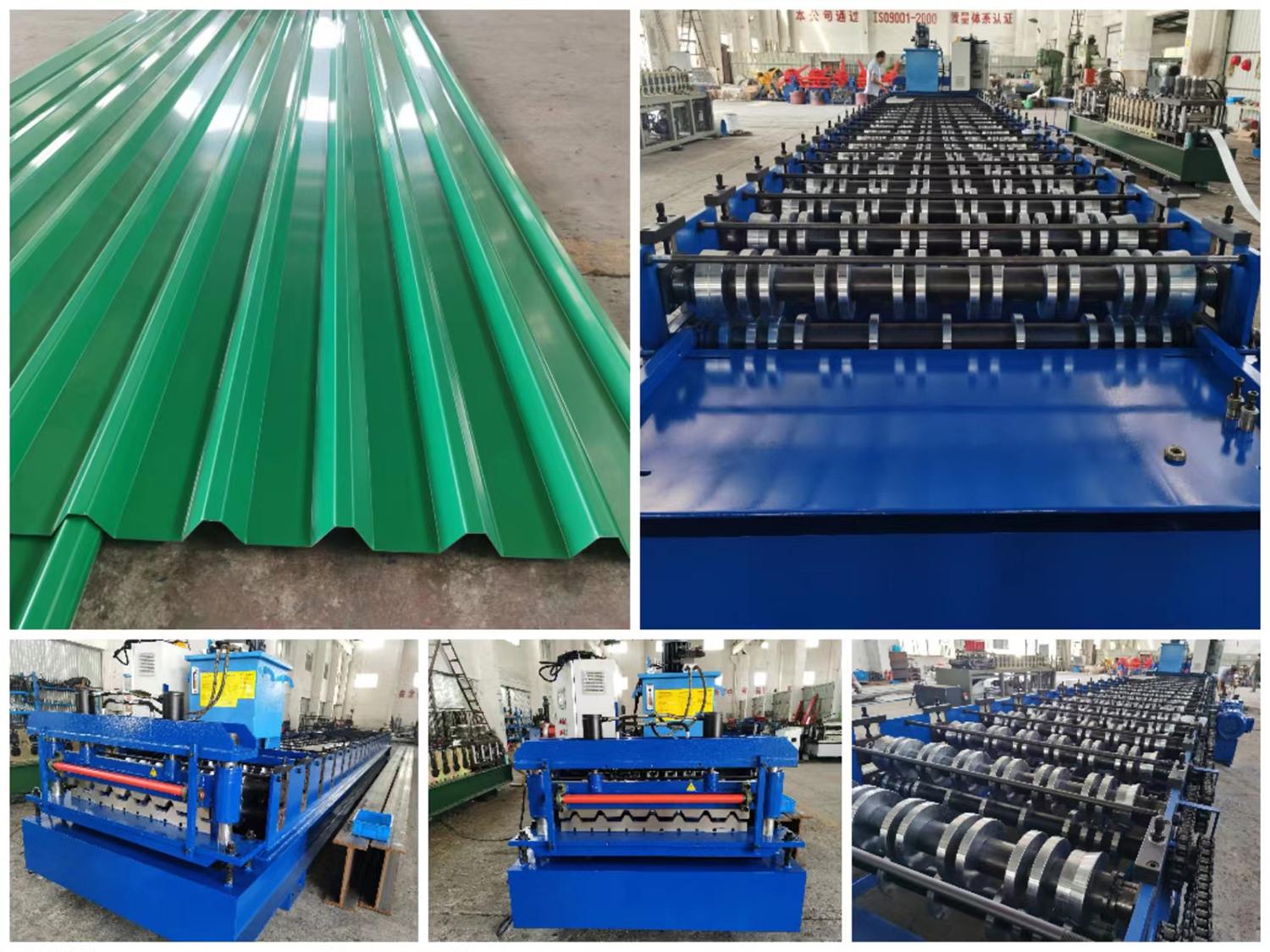

Corrugated Roof Sheet Machine Product Display

Application Scenario

Why Choose Us